Making a walk in the city center, the two of us came along the Boeken fabric store I have written about already. So we popped inside to see if there could be some nice fabric.

I had in mind to make kind of a neat shirt for "decent meetings" or so, but couln't find a fabric that would be in line with such an intention, so it became a blue denim fabric, very soft, very suitable to be processed into a shirt.

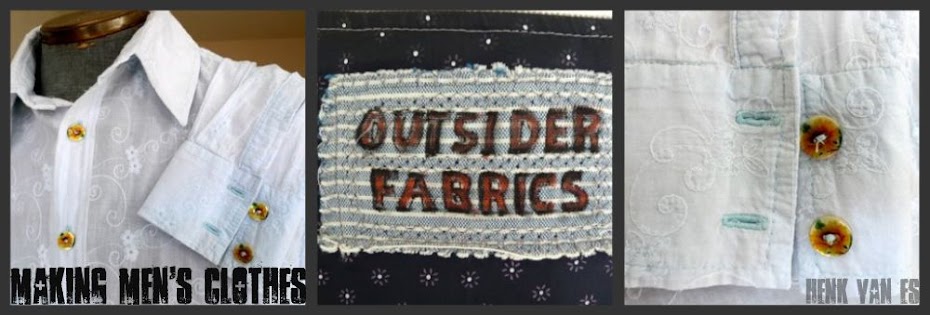

On the mannequin the shirt looks decent enough, and I sure can wear it when taking part in "decent meetings" within my social environment.

While I was busy laying the parts of the pattern on the fabric, I thought it might be a good idea to share some trics I use. For example, to most parts of the shirt I will add a seam allowance of 2 cm (0.9 inch), so -where appropriate- I arrange the parts with an intermediate space of 4 cm (1.8 inch). which makes cutting easier.

Next picture shows what these parts look like when cut: the yoke, two small side parts, the collar and the collar stand..

Using a standard seam allowance makes it easy to sew parts together. The sewing machine has markings on its foot, along which you can let move the fabric, in this way assuring you wil always have the correct width of the seam.

(Because the texture of this denim fabric has the same appearance both horizontally and vertically, I could lay all of these small parts in the same direction. If the texture is different from a horizontal or vertical position, or if the fabric has has a whiff, the yoke, collar and collar stand should be cut in a direction perpendicular to that of the front and back parts of the shirt, or in accordance with the correct direction of the whiff).

No comments:

Post a Comment